Processing of a fresh product to extract its juice involves more than just squeezing it into a container. The aim is also to increase shelflife, improve or retain taste, colour and quality and to add value to an agricultural product that might not be suitable to be marketed as a fresh product.

The principles of juice processing include proper post-harvest handling (e.g. transport, sorting and chilling), food safety, processing and packaging procedures, quality control and so on.

Some fruit or vegetables require processing-specific actions depending on the fruit shape or structure (fruit morphology) and its composition. For example, Aloe ferox cannot be processed in the same manner as peaches as the former may yield a gel-like juice while the latter results in a thick pulp. Fruit with an inedible skin, like pineapples, require peeling compared to berries which can be whole-pressed.

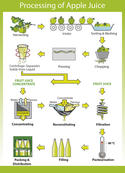

The Juicing Process

The basic principle of juicing is the breaking of the cell walls of the fruit/vegetable, allowing dissolved nutrients and moisture as well as fibres to be released. Juice extraction equipment ranges from hand operated crushers to mechanical extractors able to crush many tonnes of fruit per hour.

There are key differences in the handling of each fruit type, so only a generalised process will be described:

After inspecting and sorting received fruit, it is washed and cooled. At this stage, some fruit may undergo a further ripening process while in other fruits ripening may be slowed down to allow for scheduling of the juicing process.

Depending on the fruit type, it is then peeled, deseeded or cored before being cut up and crushed. The pulp is then treated with macerating enzymes to help with the breakdown of the cell walls and fibrous materials such as pectin and cellulose. Enzymatic treatment is often accompanied by a heat process to further increase the juice yield from the cells. Heating also softens the fruit, inactivates fruit enzymes and reduces microbial content.

Then follows pressing and extracting of the juice which is followed by straining and clarification.

For juices where cloudiness or turbidity is not acceptable, methods such as centrifugation and filtration can produce a clear juice.

During all these processes, the fruit juice was exposed to air which promotes enzymatic browning, destroys nutrients, modifies flavour and damage juice quality.

Removing oxygen is done by either flashing the heated juice into a vacuum chamber or saturating the juice with nitrogen or carbon dioxide.

The juice or pulp is then analysed and adjustments and blends are made.

The product then needs to be packaged, labelled, transported and sold. This requires that it has to have a shelf life of more than 24 hours which can require chilling, freezing, pasteurisation or the addition of a preservative. Heat pasteurisation or high-pressure processing (HPP) - a cold sterilisation technique which tends to better retain nutrients and taste - can be used for food safety when the product is packed.

Shelf-life of Juice

In warm climates, freshly squeezed juice must be consumed within 2 - 24 hours after the extraction, depending on the fruit type and ripeness.

Processes like chilling, freezing, vacuum packing and pasteurisation of juice may delay the deterioration of juice due to oxidation, fermentation and spoiling (caused by microbes and enzymatic reactions). Deterioration of juice leads to a loss of vitamins, undesirable changes in taste and appearance and the growth of possibly harmful microbes.

Packing of Juice

Packaging of juice not only helps to preserve the product but also helps to provide information about the product and attract the attention of potential buyers. It also makes it easier to transport the product and helps extend the shelflife of juice.

Historically, containers for fluids were made from plant and animal products such as woven plant fibre, calabashes, ostrich eggs, animal skins or intestines and also clay pots.

Modern juice packaging evolved quite a bit and now includes glass and PET blow moulded bottles as well as cans and laminate cardboard boxes, often made with recycled paperboard. Some juice producers may choose to supply juice in bulk containers or allow consumers to bring their own containers to fill.

Preservatives in Juice

Preservatives added to fruit juice include sodium benzoate, sulphur dioxide and sulphites, citric and ascorbic acid as well as pimaricin.

Citric acid is an additive to many drinks to enhance flavour and increase stability. It is also used in citrus juices to improve taste and increase shelflife.

Ascorbic acid (vitamin C) is often added to fruit juices to replenish the Vitamin C content which is easily destroyed during the juicing process. It is used primarily as an antioxidant to slow the oxidation process and thereby preserves colour and freshness.

It is used in wine and grape juice to control fungal and yeast development and is a non-allergenic alternative to the use of sulphates.

However, all these actions and additions alter the nutritional content of the fresh juice. If possible and practical, consumption of juice immediately after extraction may hold the most nutritional benefits.

By Marinda Louw